News

-

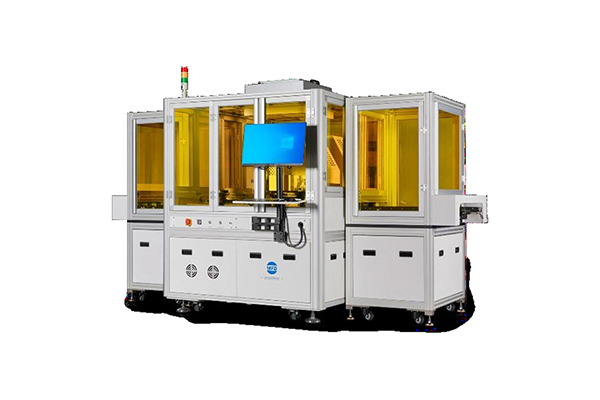

How to Balance Efficiency and Yield in Mini LED Backlight Die Bonding Machines?

The mini LED backlight die bonding machine, through ten key technologies including multi-arm structure, composite driving, intelligent vision, closed-loop control, and modular design, successfully strikes the optimal balance between speed and precision.

Learn More2025-11-04 -

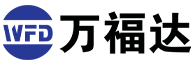

How can the rapid braking capability of a flat voice coil motor be leveraged to achieve high-precision starting and stopping?

The flat voice coil motor, with its lightweight actuator, low inertia, ironless design, direct drive, and closed-loop control, achieves extremely fast braking response and exceptional positioning accuracy.

Learn More2025-10-21 -

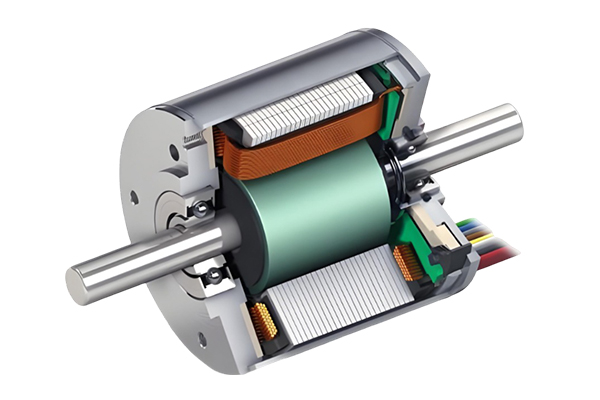

How does the back EMF waveform of a brushless DC motor affect the torque ripple characteristics?

Ideally, the back electromotive force waveform of a brushless DC motor should be a trapezoidal wave with a flat top width of 120° electrical angle.

Learn More2025-10-09 -

How can 3C automation equipment address the challenges of short product lifecycles and frequent product updates?

In the 3C industry—consumer electronics, computers, and communications equipment—product update cycles are almost unparalleled in other manufacturing sectors.

Learn More2025-09-22 -

How can CNC precision parts maintain efficient production while reducing manufacturing costs?

At the forefront of modern manufacturing, CNC precision parts, with their unparalleled precision and reliability, have become a key force driving technological progress.

Learn More2025-09-08 -

How do multi-axis motion platforms achieve ±1μm positioning accuracy to ensure high repeatability in chip bonding?

In the precision world of microelectronics manufacturing, die bonding machines have long transcended the traditional "bonding tool" to become a microscopic bridge connecting the digital and physical worlds.

Learn More2025-08-26